Last Updated on May 4, 2023 by kavin

Who is considered to be the Father of Six Sigma?

Six Sigma is a data-driven methodology for improving business processes by reducing defects and variability. It has become an essential tool for organizations seeking to increase efficiency, productivity, and customer satisfaction. The concept of Six Sigma has been around for many years, but its formal development began in the 1980s. The person who is considered the Father of Six Sigma is Dr. Mikel Harry.

History of Six Sigma

The history of Six Sigma dates back to the early 1900s when Walter Shewhart introduced statistical process control (SPC) as a method of monitoring manufacturing processes. In the 1980s, Motorola developed the Six Sigma methodology to improve the quality of their products. Six Sigma quickly spread throughout the manufacturing industry and became a standard tool for process improvement.

Who is the Father of Six Sigma?

Dr. Mikel Harry is considered the Father of Six Sigma. He was a senior engineer at Motorola when the company developed the methodology. Harry was responsible for training employees in the Six Sigma methodology and developing the statistical tools necessary for its implementation.

Dr. Harry was born on October 28, 1948, in Oklahoma. He obtained his bachelor’s degree in physics from the University of Tulsa and his master’s and Ph.D. degrees in measurement and control from Arizona State University. Dr. Harry was also a certified Master Black Belt in Six Sigma.

Dr. Harry passed away on April 25, 2017. He will be remembered for his significant contributions to the field of Six Sigma and process improvement.

Key Principles of Six Sigma

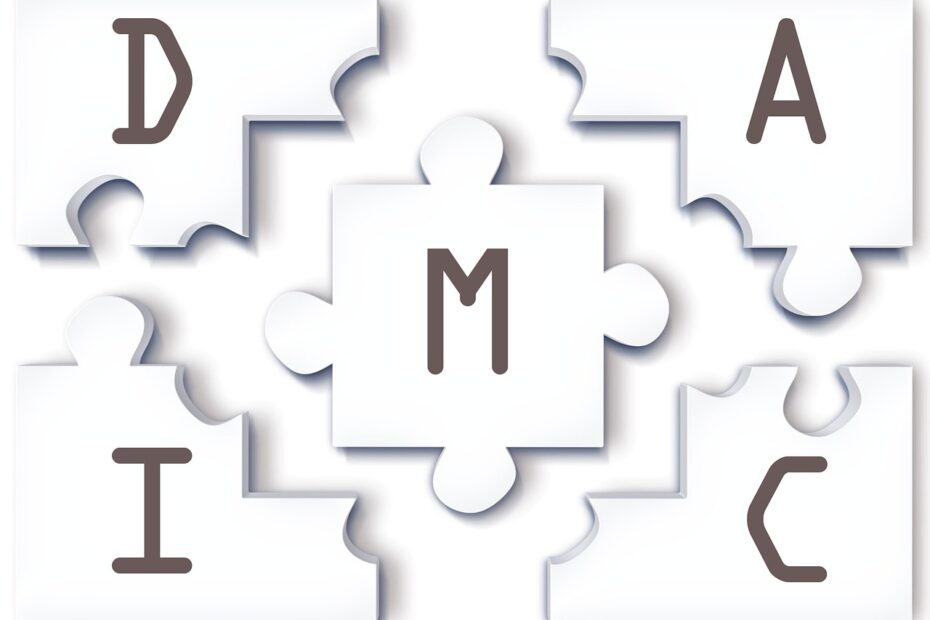

Six Sigma is based on a few key principles that guide its implementation. These principles include the DMAIC methodology and the concept of continuous improvement.

The DMAIC methodology is a structured approach to problem-solving that stands for Define, Measure, Analyze, Improve, and Control. This methodology is used to identify and eliminate defects in a process and to continuously improve the process over time.

Continuous improvement is another essential principle of Six Sigma. It is the concept of continually improving a process to achieve higher levels of efficiency and quality. Continuous improvement involves using data to identify opportunities for improvement and implementing changes to achieve those improvements.

Applications of Six Sigma

Six Sigma has been successfully applied in many industries, including manufacturing, healthcare, finance, and service industries. In manufacturing, Six Sigma has been used to improve product quality and reduce defects. In healthcare, Six Sigma has been used to reduce wait times, improve patient satisfaction, and increase the efficiency of medical procedures. In finance, Six Sigma has been used to improve the accuracy of financial statements and reduce errors.

Advantages of Six Sigma

The advantages of Six Sigma are many. Six Sigma helps organizations to achieve improved quality, increased efficiency, and higher levels of customer

satisfaction. By reducing defects and variability in processes, Six Sigma helps organizations save time and money. It also helps organizations identify areas of improvement and implement changes to achieve better results.

Criticisms of Six Sigma

Although Six Sigma has many advantages, it also has some criticisms. One of the criticisms of Six Sigma is its rigidity. Some argue that the methodology is too structured and inflexible, making it difficult to implement in some organizations.

Another criticism of Six Sigma is its overreliance on data. While data is important in identifying opportunities for improvement, some argue that Six Sigma places too much emphasis on data and not enough on other factors, such as employee engagement and creativity.

Conclusion

In conclusion, Six Sigma is a data-driven methodology for improving business processes. Its development began in the 1980s, and it quickly became a standard tool for process improvement in many industries. Dr. Mikel Harry is considered the Father of Six Sigma, and his contributions to the field will be remembered for many years to come.

Six Sigma is based on a few key principles, including the DMAIC methodology and the concept of continuous improvement. It has been successfully applied in many industries, including manufacturing, healthcare, finance, and service industries.

While Six Sigma has many advantages, it also has some criticisms. Despite these criticisms, Six Sigma remains an essential tool for organizations seeking to increase efficiency, productivity, and customer satisfaction.

FAQs

- What is Six Sigma? Six Sigma is a data-driven methodology for improving business processes by reducing defects and variability.

- Who is the Father of Six Sigma? Dr. Mikel Harry is considered the Father of Six Sigma.

- What are the key principles of Six Sigma? The key principles of Six Sigma include the DMAIC methodology and the concept of continuous improvement.

- What are the applications of Six Sigma? Six Sigma has been successfully applied in many industries, including manufacturing, healthcare, finance, and service industries.

- What are the advantages of Six Sigma? The advantages of Six Sigma include improved quality, increased efficiency, and higher levels of customer satisfaction.